Stainless steel as a basis

The Utility Line systems comply with the strictest European EEI directives for drinking water. All metal parts that come into contact with the medium are manufactured from AISI 304 or AISI 316.

Efficient and durable

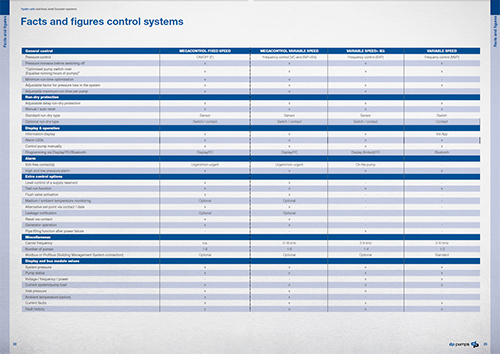

The hydraulic basis of all Hydro-Units matching a specific Q/H, is more or less the same. With identical DPV pumps, manifolds, appendages, etc. The difference between the variants is mainly it's control. Sometimes the version without speed control (DOL (on/off)) is sufficient for your application. But when there are requirements for energy efficiency, comfort or extra control options, the Utuility Line range offers enough choice. Many stories are circulating about the energy consumption of various types of pressure boosters. Ultimately, it is the combination of the purchase costs, the expected or measured operating hours, the usage pattern, motor efficiency and control that provides the best choice.

Click to display "The effect of speed control and motor efficiency on energy use"

DP-Control; Advanced controlThe Utility Line is controlled by the DP-Control pump control unit, which was developed in house. This intelligent control system provides very accurate regulation, and the system can be integrated easily into a new or existing Building Management System. The control unit can have a read out via Modbus or profibus and provides:

- System pressure

- Pump status Current system/pump load

- Supply pressure Ambient temperature (optional)

- Current faults

- Fault history

The position of the switch box is flexible, either in the technical room, or in a place of choice next to the system. This innovative design also makes the systems easily accessible for quick maintenance.

Flexible assembly and delivery times

This series of systems offers countless designs to meet the specifications of your project. Our experience and direct lines to development and manufacturing departments offer customisation, as well as unprecedented flexibility to adapt to extreme challenges concerning the delivery or specification.

|

Download documentation

> Download more documentation in our download centre

> Contact our experts

Exchange

while maintaining system pressure

Simple and responsible replacement of one pump without dismantling the suction and pressure pipes can be easily achieved with this series of systems.

The Utility Line is equipped with the discharge pipe mounted on corners so that the pumps can be sealed and easily dismantled while the other pumps remain in service. Thus, the systems that are dependant on this system can remain in service and occupants or users will experience little or no disruption during the maintenance or replacement.

Energy

efficient

In demanding environments with a lot of demand and high loads, energy consumption is an important factor. The smarter the water pressure can be provided, the less power required. And that ultimately results in a welcome reduction of the energy bill.

There are important factors that ensure the Utility Line is a very energy-efficient choice.

1. "Most energy-efficient pumps" DPV

The heart of the Utility Line is formed by the vertical DPV pumps that are developed and manufactured by us in the Netherlands in accordance with the latest energy standards. The advanced hydraulic system with high Minimum Efficiency Index (MEI) values, modern motors and a smart control system ensure the operating point is well regulated and therefore, they belong to the class, "most energy-efficient water pumps."

2. Speed control or optional expansion tank for additional energy savings

Where possible, we advise the use of a large, continuous flow-through accumulator to build up and release the pressure as evenly as possible when designing a system for an apartment building. This means the energy used up during the "mandatory" overrun of the pumps can be stored instead of wasted. Our own test set-ups have proven this method provides substantial savings.

The application of speed control on the Hydro-Unit pressure boosting systems also ensures considerable savings in energy costs.

3. Minimal pipe loss

Minimal pipe loss is taken into account in the design of the systems through the application of butterfly valves and ball valves with a full cross-sectional area and generously sized pipes.

|