DP-Pumps

best in class pump manufacturer

& the support you deserve

|

"We have the knowledge and expertise we need under one roof" |

It's the people at DP-Pumps who make all the difference. Our processes are automated because this ensures higher quality and efficiency, but consultations and checks will always be done by people. Our people work together, inspire each other and keep each other focused to make the best pumps for our customers. We control the entire development and production process of our products. That allows us to be extremely flexible for implementing clients' requirements and improvements quickly. After all, we have the knowledge and expertise we need under one roof. |

|

Material

The heart of our pumps is a hydraulic assembly made from AISI 304 or AISI 316 stainless-steel sheet metal. Impeller, stage casing and pump shroud are all formed from this high quality material. Other components, such as the shaft, the pump base and the motor stool, are procured as raw materials or semi-finished products.

|

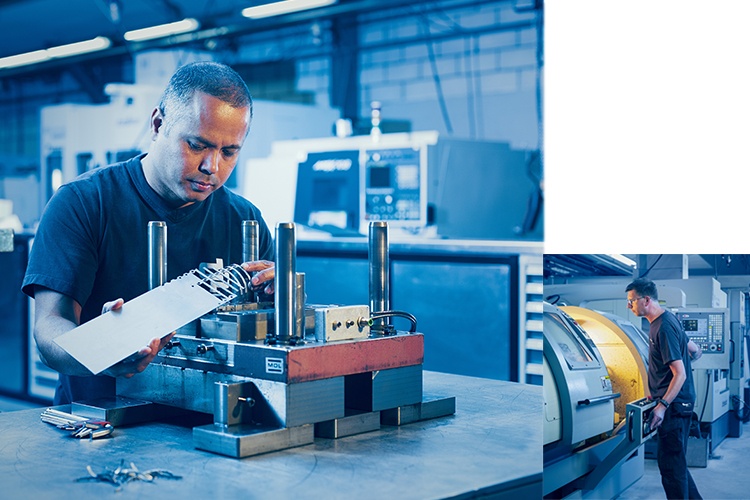

Tools'Moulds and dies precision manufactured to a hundredth of a millimeter guarantee a durable product.' Stainless steel is a great material. It is durable, wear-resistant, corrosion-resistant and very well-suited to preserve the quality of drinking water. What's more, it can be moulded into the perfect hydraulic shape. Our toolmakers use advanced electrical-discharge machining, grinders, lathes and milling machines to produce with extreme precision the moulds and dies that we need to create the perfect product. |

|

'To guarantee the highest quality,

we produce almost every component ourselves.'

Production of pump partsOur manufacturing processes are automated, thereby ensuring high quality and efficiency. However, at each step of the process, people monitor the machines.Although the welding robots visually inspect to see if the operation has been carried out correctly, the experienced operator closely monitors the process. The operator calibrates, measures and inspects tolerances and damage. These random checks are carried out at every stage of the production process. When needed, R&D and their engineering colleagues are always on hand to answer questions and solve problems. |

|

|

Motors and controlsThe hydraulic efficiency of our pumps is among the best in the world. This involves optimising each detail to achieve every last tenth of a percent of efficiency gains.The same innovation applies to motors, which are continuously becoming more efficient. In Europe, electric motors must meet the IE3 standard, but IE5 is now becoming the preferred choice. Within this standard the operation of the motor, together with an intelligent control system, is adapted by us to external circumstances. Thanks to the effective communication of the controls, our products ensure optimum energy management in every situation. 'Maximum hydraulic efficiency combined with energy-efficient motors and controls.' |

Pump Assembly

|

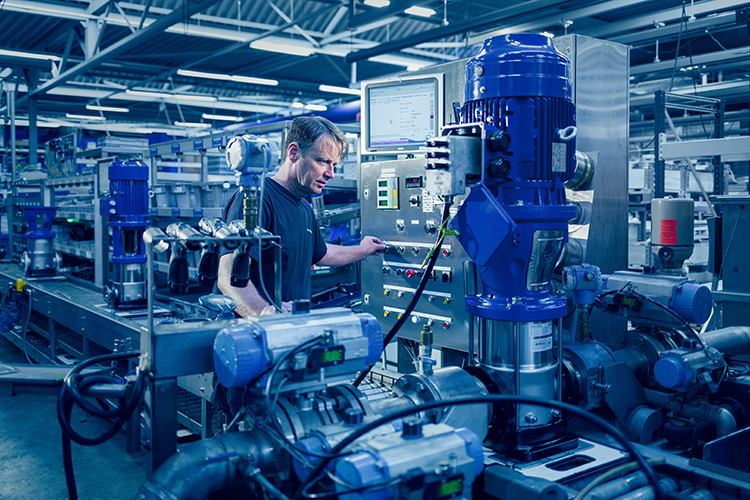

'At DP-Pumps, every pump is a custom job.' DP-Pumps assembles every pump on the customer's order. A sophisticated process enables us to easily build any of the more than one million variants of our pump configurations. To achieve this, our assembly lines are controlled using advanced Manufacturing Execution System (MES ) software. |

|

Pick-to-light; 100% flexibilityAll our processes are set-up for a fast, 100% correct production of tailor made products. This is why the technicians at the assembly lines are supported by a pick-to-light system. It shows the technician the list of materials on a screen and indicates the correct location of the parts and assembly sequence with green lights. This practical approach also makes production runs of single private label pumps efficient and error-free. |

.

|

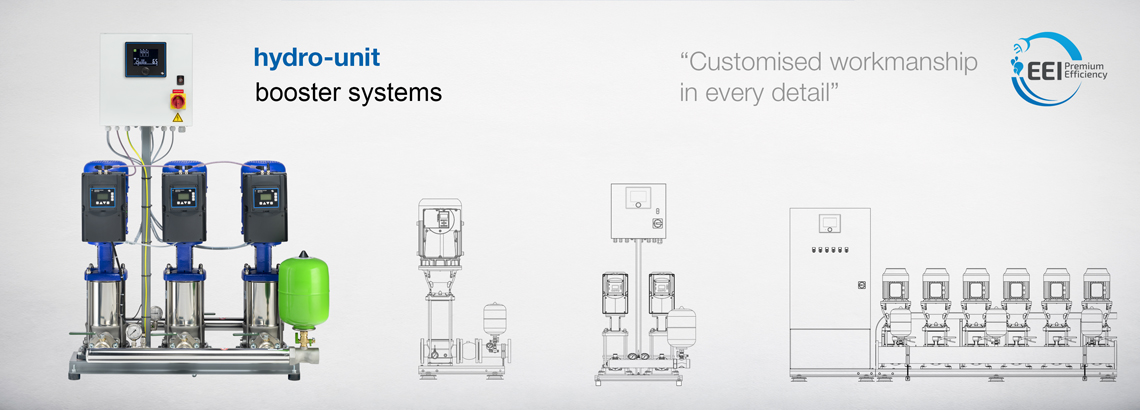

Booster assemblyIn the booster assembly department the experienced technicians who assemble our high quality pumps are strategically positioned alongside our welding shop and skilled electrical engineers. Here all the components are brought together so as to build the best booster systems. Many thousands of booster systems are produced every year for customers around the world. 'The most competitive units; customised workmanship in every detail.' |

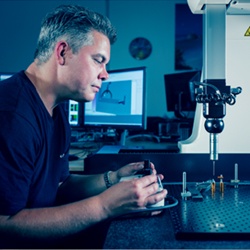

TestingDP-Pumps is committed to maximum operational reliability of its products, therefore we continuously monitor production. The quality of all materials and semi-finished products is inspected at every step of the production process.

The standard 'wet test' prior to packaging proves

that our pumps deliver the required performance and have

been extensively tested for operational performance and safety.

'No pump leaves the factory without being tested thoroughly.' |

|

The quality of all materials and semi-manufactures is checked upon arrival. |

Frequent random checks assure production quality. |

Dies and components are constantly re-inspected, |

and we perform field tests on all pump models in our research facility. |

Advice and service'Best-in-class performance. And the support you deserve.'To take full advantage of the efficient pump design, the pump must be fully tuned to the application. That is why we go the extra mile to support you during the selection process. It is easy to select the right product for your project with our documentation, selection tools and product training. If the requirements of your projects are more complex, our highly trained technical advisers will come up with exactly the right recommendations for you. If necessary, direct support from our R&D and engineering experts in the Netherlands is always available. |

|

|

|

Worldwide supportWe know just how important it is to provide good service. You want the reassurance that the pump will give trouble-free operation, and reduce downtime of the pump system to a minimum. That is why our extraordinarily good pumps come with extraordinarily good service support. We can support you with remote assistance and on-site visits when necessary. Our experts are fully trained in pump technology and will assess the total application and indicate where improvements are possible. |

|

'Innovation comes from the constant interaction between our customer, expertise and technology.' |

Research & Development |

|

With

computer simulation, advanced calculations and 3D-printed prototypes, our

engineers develop solutions to make the pumps as efficient and reliable as

possible. At the same time, we keep a close eye on

market requirements and manufacturing processes.

Therefore, product application experts, toolmakers, production workers and customers are involved in the entire development process. This kind of teamwork is essential for a thoroughly effective product, and characterises the way the DP-Pumps organisation works. It is an effective approach that only works due to the concentration of all disciplines in a single building. |

Custom designOur engineers design customised products on a daily basis. The projects can vary from the preparation of new private-label pumps to the design of specially engineered booster systems or wiring circuits for firefighting units. |

The processes in our company are certified in accordance with the following standards:

ISO9001 / ISO14001 / ISO45001

Our products

With our numerous configuration options we always make a pump or system that meets your expectations and requirements. This results in reliable, tailor-made solutions that we are proud of and know that they will do their job.

Explore our range of stainless steel centrifugal pumps

No matter the size or configuration, every booster system is made with the utmost care by our professional staff,

thereby meeting customers' specifications and local standards.

In tens of thousands of appartment buildings, hotels, ships, sport stadiums, hospitals and industrial applications our booster systems guarantee consistent water pressure for sanitary services and fire fighting installations.

Explore our range of stainless steel booster systems